Customer Services

🔪 Sharpen your edge, never miss a cut!

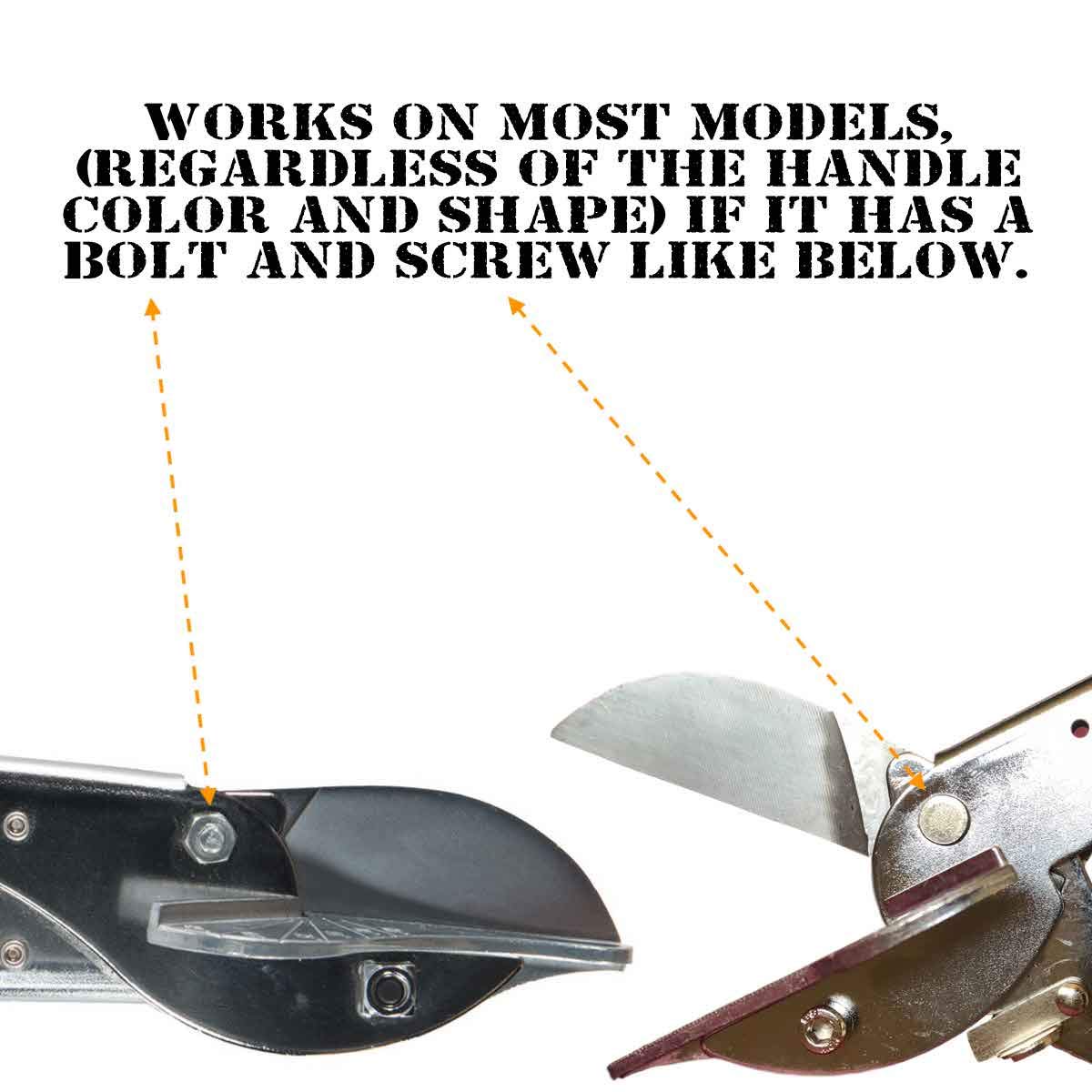

This pack includes two extra premium stainless steel blades designed for universal fit with Merhoff, Larkin, and most miter cutters. Engineered for precision cutting from 45° to 135°, these ultra-sharp blades handle PVC, wood trim, piping, and more. Easy to replace and backed by a satisfaction guarantee, they ensure your projects stay on track with flawless results.

| Manufacturer | Merhoff & Larkin |

| Item Weight | 2.39 ounces |

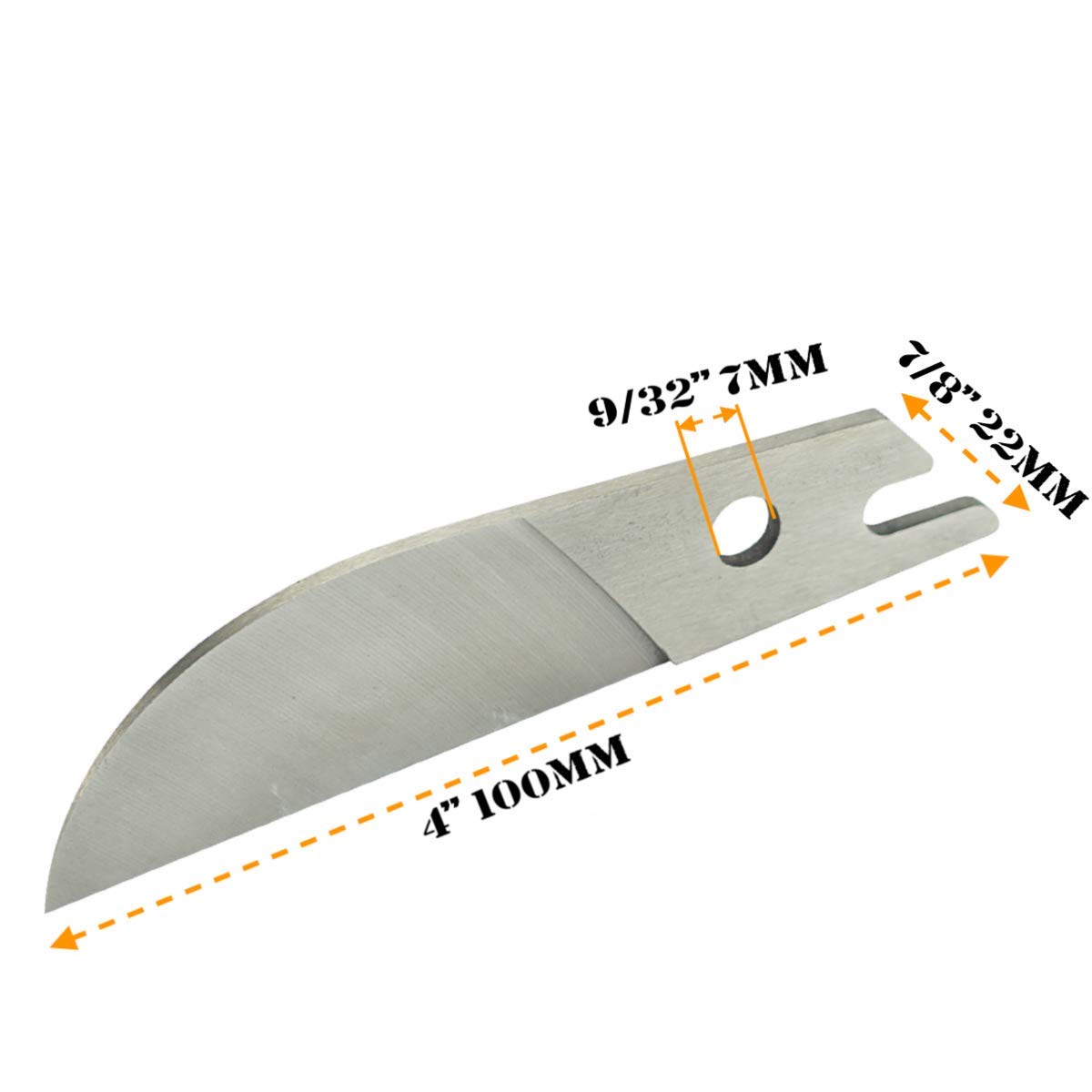

| Product Dimensions | 4 x 2 x 0.7 inches |

| Country of Origin | China |

| Size | Extra Blades |

| Material | Steel |

| Batteries Included? | No |

| Batteries Required? | No |

C**S

Nice tool for its purpose.

I bought this tool to install shoe molding and it works well. To be fair, I've only used it a few times so far but it cuts a nice smooth cut on whatever angle you need. Saves trips back and forth to the saw and time is money.

G**

Great fit

The blade fit great with my lowe qtr round cutters . Easy to install .

K**D

Blade chips when trying to cut 1/4" Screen moulding - as predicted by many users.

Love the accuracy and solid build of the device. Using it to cut screen moulding - foam moulding is fine, but pine is not easy to cut... chipped the first blade that was with it. (Have two extras that were ordered with it, expecting the chip to happen) I just took my file and smoothed off the rough edge and continued cutting... will continue to cut the foam mouldings, but will use the device ONLY to mark and score the would mouldings and then use my coping saw to finish the job...Not a big deal, since this device requires less equipment - miter saw, miter box or miter chop saw... save considerable time for me and gives me exact cuts...Blades need to be made like knives, not like razor blades... I can sharpen the blades with a file or a dremel...I would recommend this to others...

D**E

used for cutting window screen trim

Used it for cutting vintage window screen trim about 1/4" x 3/4" white pine or fur. Needed to cut 200+ 45* angle cuts and this did it and is still sharp. The wood not being balsa wood took a two handed grip to cut and some of the trim was harder than others but saved a huge amount of time, no marking, no sawing, no sanding, no splinters just a clean smooth cut. Actually burnishes the end of the wood leaving it slightly shinny and very pro looking, actually better than a pro finish.

C**S

Didn’t work out. Got returned.

Unfortunately it didn’t work out to trim quarter rounds efficiently and with a clean cut (the work will not pass your wife’s quality control). After a few cuts, the angle plate got loose and needed to get tight ... although just a few cuts helped to figure out that this was not the correct tool for me, the razor already lost cutting power (a spare razor comes with the package), but I was surprised about just with a few cuts the performance dropped considerably. Returned and got money back without any issues.

F**S

Design Flaws Reduce Accuracy

This is a well built set of cutters, and the extra blade is nice, but there are design flaws that limit usability. Under the blade on the anvil of base cutting area are grooves for the blade to sit in below the cutting surface after a cut is made. This seems fine in theory, but what it results in is the blade unable to cut through the material as the material is unsupported and gets depressed into that groove. Small strip wood gets mostly cut but has a lingering bit at the end as the cut is not complete. The blade more or less mashes its way through the cut. A ragged end is the result. That was with 1/16" square basswood strips. Larger wood strips like a popsicle stick yielded similar fuzzy results.Styrene is my primary modeling material. Plastic strips cut were square, which is good, but the blade mostly compressed the plastic, not shearing it edge was mashed down and would need dressing up with a file.CHANGES NEEDEDThe blade is not a pure single edge grind. It has a slight back bevel to the blade resulting in a V knife edge that compresses, not cut. It may be possible to hone the back bevel back to flush so it cuts on one side only.Filling in the surface anvil/cutting surface with epoxy and filing it flat and flush might prevent the material being cut from being pushed into the relief slot.More expensive or better cutters might already address this. I have never had a set before so I cannot compare. This was cheap enough to try, and I might mod this to something more usable for my use case. Otherwise it is going to sit in a drawer forgotten.UPDATE:I couldn't wait to try modifying the tool and immediately tried putting a couple of layers of masking tape across the surface to raise the cutting area. This fixed the incomplete cut issue, but tape is not a long term solution, plus the miter fence could not swivel. I used some 0.020" thin plastic sheet to glue to the surface. I disassembled the plate to do so. A separate small piece was used for the rotating fence. A bit of super glue and a sharp modeling knife to trim the excess away afterwards and it was done.Now the blade shears the material instead of compressing it. Perhaps more expensive versions have this already addressed, but a bit of plastic sheet (Evergreen Styrene) and it is now usable.

L**T

Works like a dream

I use this to cut 1/4' square dowels. It cuts right through with ease, and you can miter corners at different angles or just cut it straight. It made the process so much faster for me!

R**.

Amazing!

Such a nice tool. Very much a time saver!

Trustpilot

1 month ago

2 months ago