Customer Services

Cutting-edge craftsmanship at your fingertips! ✨

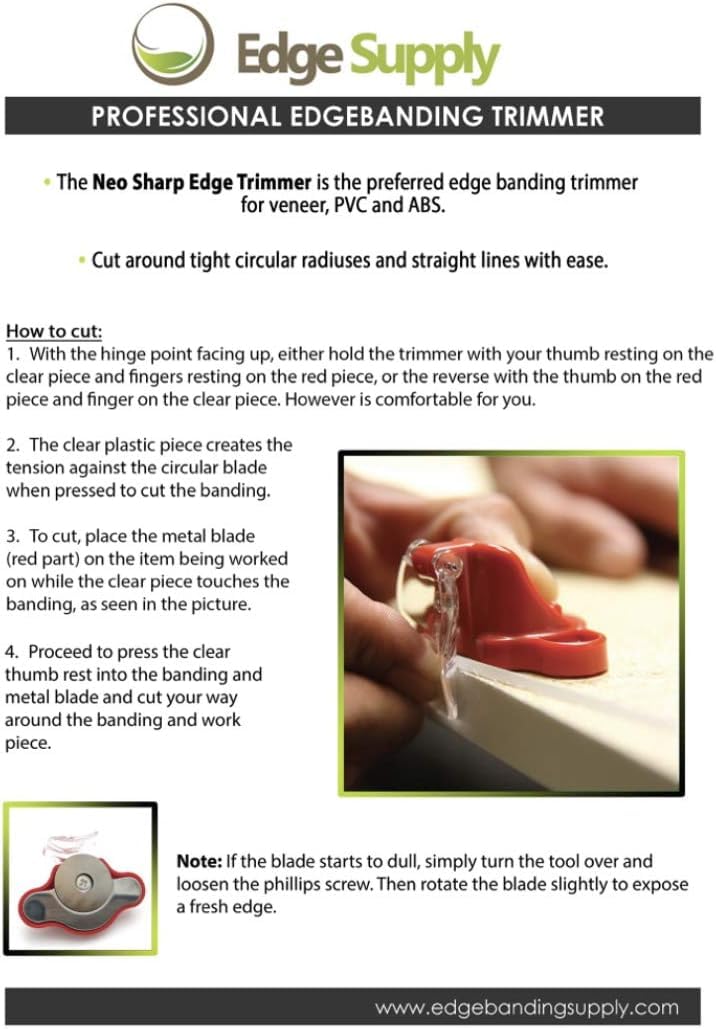

The Edge Supply Single Side Edge Banding Trimmer is a premium tool designed for precision cutting of veneer edge banding. With its ultra-sharp carbon steel blade, it effortlessly trims edges up to 1 mm thick and 2 inches wide, making it ideal for a variety of woodworking projects. Lightweight and user-friendly, this trimmer is perfect for both professionals and DIY enthusiasts, ensuring clean, flush finishes every time.

| Item Form | Bar, Rod |

| Number of Items | 1 |

| Manufacturer | Edge Supply |

| Part Number | 712048503169 |

| Item Weight | 1.94 ounces |

| Package Dimensions | 4.76 x 2.36 x 2.28 inches |

| Item model number | 712048503169 |

| Is Discontinued By Manufacturer | No |

| Finish | birch finished |

| Batteries Included? | No |

| Batteries Required? | No |

R**2

Is this thing worth $60? For me, it's a resounding yes.

Okay, so on the surface $60 for this thing is insane. From a sheer manufacturing standpoint, no, there's no way the manufacturer can rationalize a $60 price point. With that being said - it's worth every penny!I was using my Festool router table, Festool OF 1400 router, and a Freud cutoff/tracing bit. I am working with prefinished 1/2 and 3/4" edgebander maple. The smaller pieces worked well enough on the table, but as the pieces got bigger it wasn't feasible to run them through it without the router bit "biting" into it occasionally.....even with the tracing bearing.So, these are my options:1) Use a utility knife. It works.....kinda. Leaves a horrible edge that'll need to be cleaned up, plus the blade can easily slice too far into the banding.2) Use the two sided spring loaded trimmer that goes down both sides at once. Blades dull rather quickly, and you find out the hard way that given the grain of the real wood edgebanding it's sometimes not wise to expect to be able to do both sides at once. Sometimes this works perfectly, but sometimes it'll dig in badly and "tear out" part of the edgebanding.3). Use one of my small laminate routers freehand.....like the Bosch Colt. On half inch material this is tricky because it rocks on the top. Yes there are edge guides, but the uncut edgebanding itself protruding doesn't allow these guides to work well. The 3/4" isn't nearly as hard to balance the Bosch Colt on, but I don't have dust extraction on this tool and considering how close you have to be physically to monitor your progress you can really get filthy. I believe Festool has a laminate router and special attachments (OF 700 router) that'll allow for a presumably perfect edge, and you can hook up dust extraction. If you have none of this expect to pay about $1500 for it all.4). Get this tool. It works 95% perfect, 95% of the time. I mean not even needed to be sanded level of perfect. Seriously. The biggest problem is the adhesive will build up on the blade and will need to be removed occasionally. That happens with all of the above methods as well, though....including and perhaps especially the router bits, which have a tendency to melt the glue as they travel....even at the lowest setting.So, is it worth $60? Unless you already have the Festool OF 700, the attachments, and a dust collector......it's a resounding yes. Even if I had those things, I would likely STILL use this little plastic gizmo because it's faster and easier and can actually result in a BETTER finish than a router especially designed for just this.Trust me, buy it. The first time you run it up the side of a long edgebanded piece you'll probably let out a "Holy crap!" just like I did, then wonder how you ever lived without it.

T**.

Great tool once you learn its quirks

I originally did not care for this tool at all and was ready to send it back. I did a little more experimentation and found out that with light pressure I could cut through the material in 3 or 4 passes instead of trying to do just one, which resulted in a rough edge or tear out. It takes a bit of finesse to do this, but I found by pulling it towards me with a very light touch it works well. The glue tends to build up pretty quickly, so keep some alcohol handy and a screwdriver for rotating the blade. I kind of wish the plastic portion lifted up out of the way for cleaning. The only way to get the glue off the blade is to loosen the screw and rotate it or remove it all together and clean it. That gets old as it gums up pretty much every time you use it. If you don't keep the blade clean you are bound to get tear out.And I also found just by letting the glue set up (cool) for 30 minutes or so instead of trimming immediately will help with the gumming problem. That seems to be the problem with just about every trimmer I've used. None are immune to the demon glue.I still don't think this thing is worth anywhere near the $60 considering it's really nothing more than a rotary blade and a dollar's worth of plastic, and you can't even buy replacement blades! There is nothing else on the market that works quite as well though, so they've got you!And I do find with this style of cutter a greater amount of overhang is better than a minimal amount. So something like 1" wide edging versus 13/16 for 3/4" plywood is better for a clean cut. A smaller overhang is more likely to tear or chip out.

J**R

This tool is a MUST-HAVE!

If you are edge-banding with Fast Edge peel and stick, this tool will save you hours of trimming and is super low maintenance. Just clean the tool of residue adhesive every now and then. Also make sure the hinge pin stays properly set. Once you get the technique down, you can trim a panel in like 30 seconds! I even trim the ends with this, cuz it really does cut flush - consistently. I still haven't even rotated the cutter for a fresh edge to cut with. Love it! Super worth the price to my small production shop. You can pretty much walk away and it's done. You'll have just a super thin line of adhesive residue along the edge that you'll just need to clean off (I use lacquer thinner). I usually clean up after the build. I honestly haven't used it to trim the iron-on edging yet. That stuff chips a lot so I wouldn't be surprised if it doesn't trim perfectly. Seriously, buy this. No more POS trimmers for me. There was a lot of thought put into this, and these guys nailed it. Buy it! I'm out.

M**R

Not worth the money.

This is not worth the money. The blade dulls rapidly and it’s nearly impossible to unscrew the mechanism that allows you to turn the blade to a fresh side. The plastic piece is not properly attached so it falls off constantly. Trust me, it’s not worth the $60.

N**7

Fatal Flaw

As a cabinet maker I use iron on edge banding for frameless cabinets and shelves, so trimming the edge banding needs to be clean and efficient. This trimmers cuts are decent but lacking. Since you’re pressing the edge banding in to the cutting edge it doesn’t tear the edge banding like using a wide blade chisel can (the way I’ve done it for over decade). But it does tend to follow the grain not give a super clean cut. And as far as efficiency goes it’s as fast when I use a chisel which is pretty quick.Now for the fatal flaw. Because the blade is circular the leading edge can and will cut in to and ruin plywood veneer. In my picture I was trimming birch edge banding on 3/4” birch plywood for some shelves in a kitchen I’m building, the trimmer caught a grain shift in the plywood veneer and ripped a bid chunk of veneer off. I had to make a new shelf because of this. This trimmer may not do this on all veneers/plywoods but I’m not going to take that chance.

Trustpilot

1 day ago

2 months ago